The Future of Production Organization

Our software for management execution systems strikes the perfect balance between diversity and flexibility on the one hand, and short lead times with low stock levels on the other. 3Tec produces small batch sizes for you – efficiently and transparently!

For many years now, 3Tec has been using its software expertise and experience to further develop the automation processes used in industrial production. We specialize in the latest management execution systems, experienced in the field of machine and warehouse control systems, and always work with one goal in mind: to control processes efficiently in order to give our clients the best results possible.

Modern Control Technology for Machines and Plants

We provide precisely developed control technology that has been perfectly tailored to your on-site conditions in order to guarantee process reliability for your production. 3Tec machine control and plant visualization techniques are reliable and powerful!

WMS / transport logistics

Save Time and Resources with our Warehouse Management

Efficient warehouse management with smart technology! Our Warehouse Management System (WMS) optimises your inventory management, minimises errors and increases productivity. Thanks to real-time data and intelligent control, you always have an overview and maximise your warehouse capacities. Rely on digital processes for fast, precise and cost-efficient logistics!

Our standardized warehouse management systems allow us to optimize the way that technology and warehouse staff interact. 3Tec supplies management and control systems that save on time and movement for both automatic and manual warehouses!

Customer degrees of freedom

Customer degrees of freedom refer to the scope that customers have with our services and user interfaces. Customers can choose between different variants, modules and customised configurations. This concerns, among other things:

- Open SQL databases

- Programme generators

- Print generators for production documents

- Dashboard

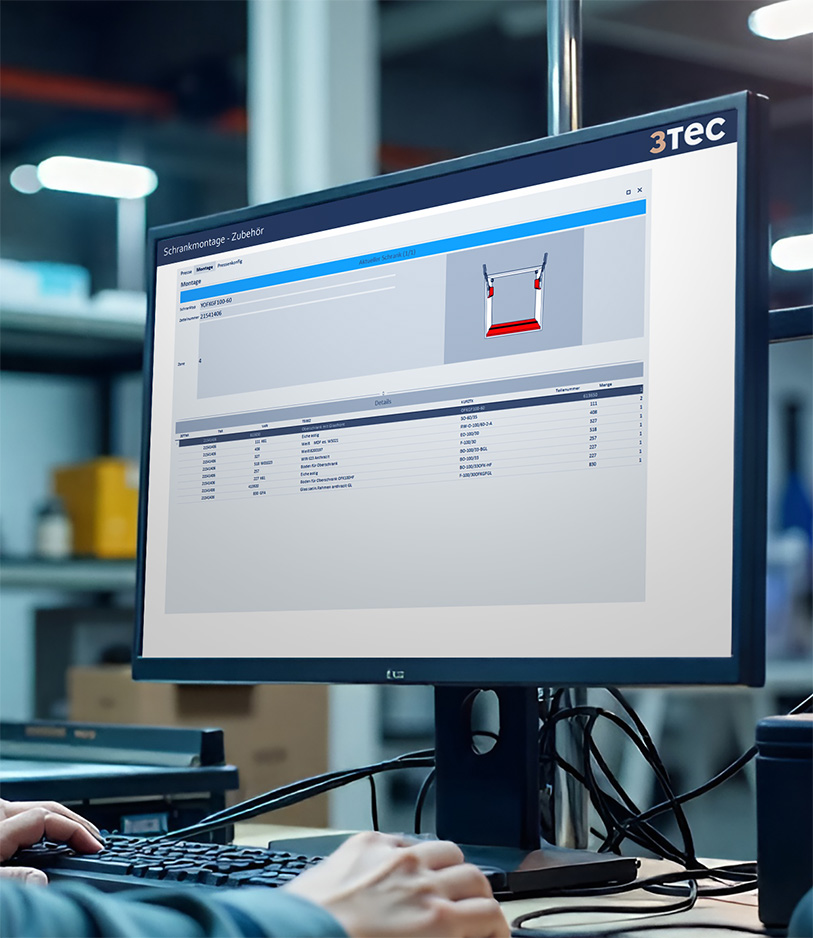

Automation / Production control system

In a production control system, information for the production sequence is determined. The workpiece flow through the factory is controlled and monitored by the production control system. When complete plants or individual machines are connected with the production control system, all movements of workpieces are carried out automatically. The necessary processing data are transferred to the individual machines at the right time. At the highest level, complete factory areas can produce in an unmanned way.

A batch size 1 plant with automatic transport of parts between from machine to machine requires the fastest reaction times of the complete system. In 3Tec systems the transport routes are always decided just-in-time in order to be able to react immediately to any factors influencing production (machine failure, reproduction etc.). The scope of delivery includes:

- Labelling

- Parts tracking

- Stack formation

- Sorting

- Batch management

- System visualisation

- Feedback to ERP

Transparency

Intelligent control for efficient production! Our production control systems optimise production processes, reduce throughput times and increase product quality. With real-time data and smart analyses, you can control your production precisely and flexibly. Utilise digital intelligence for maximum efficiency in production!

3Tec production control systems furnish information about the actual production status. The production control system recognizes every component individually. Workpieces or stacks are either identified by barcode scanning or by automatic tracking. Scanners, RFID, machine feedback or operator input are the information sources. This enables our:

- Production progress display

- Capacity overview

- Completeness check

Information points with:

- work instructions

- Machine connection

- Edge preview

- Assembly information

- QM

Production planning

Perfect planning for maximum efficiency! Our intelligent production planning optimises processes, reduces downtimes and increases productivity. With real-time data and smart analyses, you always have an overview and can make well-founded decisions. Rely on digital planning and take your production to the next level!

The production control system determines which orders or batches should be produced. The complete information regarding current production, utilization of machines, and inventory in the warehouses is known. An automatic or semi-automatic planning of production units is only possible with this information. Reproductions, quick fix orders and cancellations are promply and efficiently taken account of. In detail these are:

- Data transfer from ERP

- Planning

- Capacity control

- Lot creation

- Optimisation

- Post-production organisation

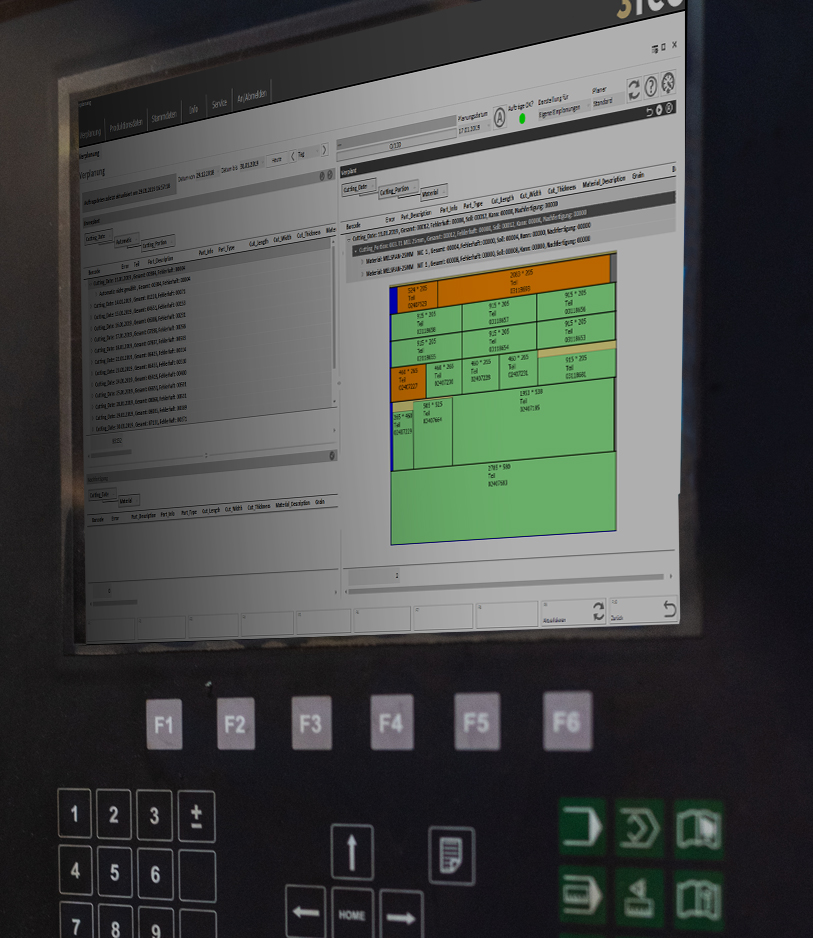

Offcut optimisation

More efficiency, less material waste! Our solution for offcut optimisation of panel material maximises the use of your raw materials and reduces waste to a minimum. With intelligent calculation and precise arrangement, you save costs and increase your sustainability. Optimise your processes and get the best out of every cut!

Optimization modules (1D/2D) are frequently used with 3Tec systems. Often the algorithms must be individually adjusted, because (apart from minimizing waste) there are other important factors:

- Depending on machine configuration, capacities of buffers and sorting units are taken into account

- Production sequence, e.g. in order to keep orders together

- Consideration of machine limitations

- Simultaneous presentation of different optimization results (with/without optional parts, with/without remnant boards etc.)

- Production with or without optional workpieces

- Controlled consumption of remnant boards (depletion of remnant board stock)

- All standard optimisation systems (Ardis, Schnitt Profi(t), HPO, etc.) can also be used

MDE/BDE/PZE

Optimised data acquisition for maximum efficiency! Our MDC/PDC systems enable seamless recording and analysis of operating and production data in real time. This increases transparency, improves your processes and minimises sources of error. Rely on digital intelligence and turn data into decisive competitive advantages!

Much of the information required for production statistics exists in the production control system. Additionally, information is recorded:

- at information points (quantities)

- at individual machines (times for production, break, refitting, breakdown)

- Shop floor data / Statistik

- OEE / KPI

Program generator

The 3Tec program generator is a development system to create customized production data that the ERP system is unable to provide.

The following application areas have already been realized:

- Creation of processing programs for furniture

- Part programs for side parts/shelves

- Part programs for fronts

- Cabinet programs for carcass production

- Creation of processing programs for worktops

- Part programs for worktops

- Edge information

- Creation of production data

- Determination of operation plans for production cycles

- Adjustment and extension of machine-independent programs for different production

- Transformation of customer-specific programs into machine-related formats

Material flow control

Efficient processes through intelligent material flow control! Our solution optimises the route of your materials, reduces bottlenecks and increases productivity. Thanks to smart automation and real-time data, resources flow exactly where they are needed. Use digital control for smooth and cost-efficient production!

Automation of in-plant material movements with barcode and transponders:

- Visualization and control of transport routes and handling systems

- Control by means of fill levels and utilization

- Dynamic determination of processing paths

- Generation of transport paths from operation plans

Special machines

In co-operation with other mechanical engineering companies, 3Tec supplies user interfaces for different applications in many industrial sectors - from individual machines up to complex, interlinked plants:

- Packing machines

- Hydraulic cylinder production

- Production of sectional doors

- Door and frame production

- Prefabricated house industry

- Automobile suppliers

- Veneer sector

High-bay Rack Storage

- Multi-aisle systems with/without aisle change of rack retrieval system

- Optional shelf arrangement (side by side/one after the other)

- Dynamic generation of storage space requirements in the cantilever storage rack

- Sorted and mixed compartments and storage places

- Handling of stacks and individual boards

- Creation of commissioned stacks in the rack retrieval system

- Adherence to load distribution parameters

Area Storage (overhead crane)

- Single and multiple crane bridge systems

- Support of different load pick-up methods

- Vacuum suction traverse (also adjustable)

- Gripping systems

- Stack lifting cages

- Weight measuring for secure pick-up of individual boards

- Geometry-dependent suction activation

- Minimization of stacking times in chaotic operation (mixed panel stacks) through intelligent depot concept

Sorting Systems

- Gantry and rack systems

- Telescopic or suction gripping

- Storage types

- Storage of individual boards with direct pick-up

- Storage of packages of similar parts with gripping

- Stack storage of different parts with re-stacking processes

- Different concepts for storage and sorting

- Capacity-based distribution

- Arrangement of associated parts

- Route optimization

- Optimal utilization of storage capacities (high packing density)

- Take account of urgent orders

- Permanent control of completeness of orders/commissions

- Dynamic allocation of similar parts during retrieval (also for urgent orders)

Forklift guidance systems

Maximum efficiency in forklift truck logistics! Our innovative forklift guidance system technology ensures optimum route planning, reduces empty runs and increases productivity. With intelligent algorithms and real-time data, your industrial trucks move precisely and reliably through your warehouse environment. Use smart control for lean, efficient intralogistics.

Automated Guided Vehicle

Efficient logistics starts with intelligent control! Our solution for driverless transport systems optimises your material flows, increases productivity and minimises errors.